Description

Features:

- EXAIR's Super Air Wipe, with stainless steel hardware and shims, provides a uniform 360° airstream that is ideal for blowoff, drying, cleaning and cooling of pipe, cable, extruded shapes, hose, wire and more.

- Model include stainless steel braided hose which feeds both halves from one compressed air inlet.

- The split design offers easy clamping around the surface of the material moving through it, eliminating the need for threading.

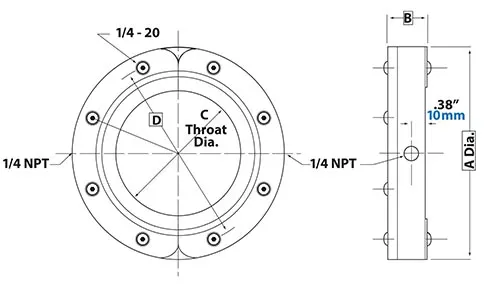

- Compressed Air Inlets: The Super Air Wipe has compressed air inlets on each half. A stainless steel braided hose connects the air supply from one half to the other.

- Mounting: The Super Air Wipe can be supported by the compressed air supply pipe. Tapped holes (1/4-20) on the downstream side of the Super Air Wipe can also be used for mounting.

- Regulation: A pressure regulator on the compressed air supply provides infinite control of flow, force and air consumption.

- Type 303 Stainless Steel - This is the most common grade of stainless steel. It offers good strength and is best suited to mildly corrosive environments. It can withstand temperatures up to 800°F (427°C).

- 1" St. St. Super Air Wipe

Applications:

- Drying after washing, cleaning, plating or coating

- Blowoff dust and contaminants

- Cool hot extruded shapes

- Uniformly wipe surfaces

- Dry extruded profiles, rod and medical tubing

- Eliminate solution carryover - no cross contamination

- Blow excess water from automotive door gaskets

- Remove excess coatings, water and oil

- Dry tube, hose, wire, fiber optics

- Minimize solution loss due to drag-out

- Clean paint gun tips

- Dry screen printed or ink jetted surfaces

- Clean strips and ribbon

Advantages:

- Quiet

- Low air consumption

- Uniform 360° airflow

- Uniform airflow across the entire diameter

- Stainless steel hardware resists corrosion

- Stainless steel model for temperatures up to 800°F (427°C)

- No electricity, no moving parts

- Non-contact - no wiper blade

- Split design - compact, rugged, easy to install

- Lightweight, low profile

- Tapped holes for mounting

- Variable force and flow

- Meets OSHA maximum dead end pressure and noise requirements

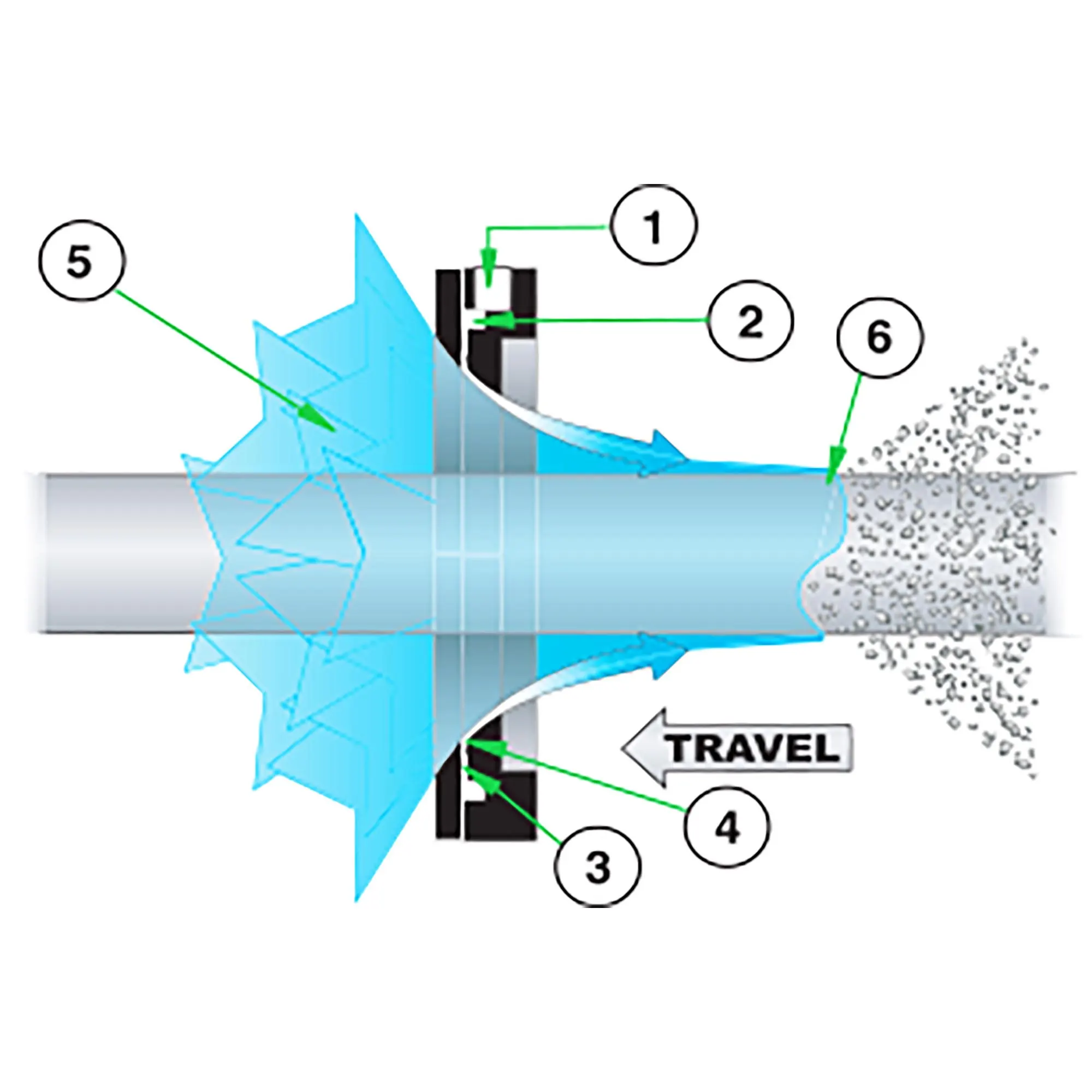

How it Work:

- Compressed air flows through an inlet (1) of the Air Wipe into an annular chamber (2). It is then throttled through a small ring nozzle (3) at high velocity.

- This primary airstream adheres to the Coanda profile (4), which directs it down the angled surface of the Air Wipe.

- A low pressure area is created at the center (5) inducing a high volume flow of surrounding air into the primary airstream.

- As the airflow leaves the Air Wipe, it creates a conical 360° ring of air that attaches itself to the surface of the material running through it (6), uniformly wiping the entire surface with the high velocity airflow.

⚠️ Attention CA Residents: Prop 65 Warning

- You May Also Like

- Your Recently Viewed

- Reviews

- Q&A

Technical details

| 80 PSIG (5.5 BAR) | |

| Air Consumption (SCFM) | 19.1 |

| Air Consumption (SLPM) | 541 |

| Sound Level at 3' (914 mm) | 80 dBA |

| Dimensions | |

| A | 3.75 in / 95 mm |

| B | 1.13 in / 29 mm |

| C | 1 in / 25 mm |

| D | 2.95 in / 75 mm |

Questions & AnswersHave a Product Question?

Reviews

Leave a review of this product!

If you've used this product, please leave a review to tell us and other customers what you thought about it. Get paid up to $16 for submitting one of the first text, photo, or video reviews for this item. Please contact us for more details.

Write a text review

Earn $2.00Post a product photo

Earn $4.00Post a product video

Earn $10.00